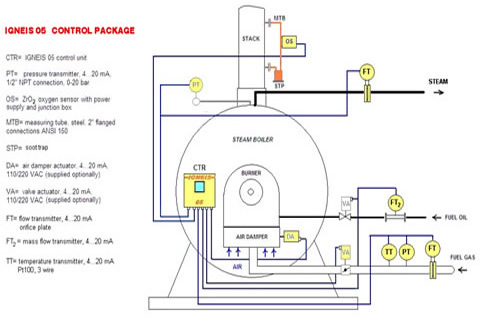

IGNEIS 05 is a combustion optimization system for steam boilers, designed for obtaining optimum combustion and minimum fuel consumption at any firing rate. This is achieved through the use of separate actuators for fuel and air, a software characterization of the air-to-fuel ratio, oxygen to firing rate characterization and automatic correction of the air-to-fuel ratio.

- The IGNEIS 05 package consists of the following components:

- - Control Unit IGNEIS-CP05, containing a programmed controller, field terminals and the local operator´s interface with a 5.8" color touch screen, Ethernet port 100 Mbit/s

- - Pressure transmitter, 4...20 mA signal output

- - Zirconoum oxyde (ZrO2) oxygen sensor , with factory assembled cable, 2 m

- - Meauring tube for stack mounting, with an Evaluator/Transmitter for oxygen sensor in a NEMA 4 metal housing, 4...20 mA signal output

- - Modulating actuators and variable speed drive with 4...20 mA or serial signal input.

System Functions are:

- • Steam pressure control with PID algorithm

- • Combustion control

- • Air-to-fuel characterization with up to 30 points

- • Characterized stack oxygen control

- • Alarm displays for oxygen and steam pressure.

- • Operation through local and optional remote terminal

- • Ethernet communication

IGNEIS 05 is adaptable to any type of boiler.

Downloads:

IGNEIS 05 - Introduction

IGNEIS 05 - Fuel Savings Calculation Sheet

IGNEIS 05 - Control Unit